The final mechatronic product is only as good as its components (including software and integration). With rising product complexity, especially in the automotive industry, aligned processes are the cornerstone of product developments.

Complexity that fosters higher product quality

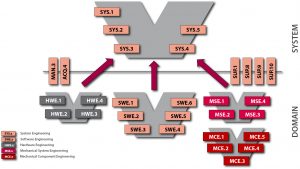

ASPICE is an extendable process assessment model, intended for use when performing conformant assessments of the process capability on the development of embedded automotive systems with major focus on software development but not limited to that. The model incorporates governance, maintained by automotive companies, and assessment. The later requires that projects follow engineering best practices. Due to its complexity, it requires extensive efforts to achieve compliance.

As a supplier of mechatronic solutions to various companies in the automotive industry, IM set out to embed the model into our processes, to optimize and enhance, and deliver quality products to customers. While adopting the model throughout the organization, our main realization was, that collaboration and transparency in partnerships are paramount to meet individual assessment levels.

Benefits of using ASPICE in the engineering process

ASPICE sets guidelines for development, integration, collaboration and required testing processes and sets six levels of capability. It also defines how a process will be assessed. It serves as a complementary, or rather, overarching model alongside other automotive standards.

Main benefits of ASPICE:

- Identification of possible errors in early stages of product development,

- Cost optimization achieved via early error elimination,

- Considerable time savings during product development cycle,

- Increased reliability when it comes to developing complex products (including software, hardware, mechanical parts, …),

- A robust, thoroughly tested component ready for further integration,

- Improved organizational performance.